Installation & Finishing Accessories

Vetted by Our Seasoned Flooring Experts

Metropolitan, manufacturer and distributor of Evoke flooring, has assembled a technical services team of veteran flooring installers and experts. These experts carefully review and tests all flooring accessories, recommending products based on performance, quality, and design.

Find everything you need to install, finish, and maintain Evoke laminate, luxury vinyl, rigid core and Surge® flooring through Metropolitan, including underlayments, trims and transitions, and care and maintenance products.

View all flooring accessories available through Metropolitan.

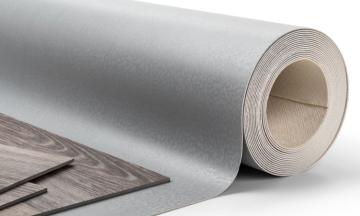

Installation Accessories

For a professional flooring installation, Metropolitan offers a curated selection of recommended vinyl adhesives and complementary underlay and acoustic solutions, including:

Finishing Accessories

Color-matched trims and transitions are the finishing touches of any flooring installation. They elevate a floor and give it a custom look that is difficult to achieve with off the shelf products.

Evoke trims and transitions are available in PVC or moisture-proof MDF.

Contact us to inquire about the different types available, or visit Versatrim, a trusted moldings partner, to view finishing accessories online or to place an online order.

Evoke Trims & Transitions

Contact Us

Have a question about Evoke flooring accessories or need assistance placing an order?